SunPlower:

Turning a 100-Year-Old

Dream into

Reality

Where are the

Wheels for Air?

A propeller/wheel which looks like the SUN!

We, humans, are using wheels (Rad - German/ Rath - Sanskrit) for ages. We use the 14th-century screw almost everywhere on land, air & water!!

Wheels cover 10-15x more distance (2πr) in comparison to a screw which moves only by 1 pitch per rotation. Wheels are faster and smoother compared to noisy and cutting (birds & fish) screw propellers.

The fact is we still don't have the compact wheel for air which is effective & efficient!

We, humans, are using wheels (Rad - German/ Rath - Sanskrit) for ages. We use the 14th-century screw almost everywhere on land, air & water!!

Wheels cover 10-15x more distance (2πr) in comparison to a screw which moves only by 1 pitch per rotation. Wheels are faster and smoother compared to noisy and cutting (birds & fish) screw propellers.

The fact is we still don't have the compact wheel for air which is effective & efficient!

The Propeller That Was ‘Impossible’ for 100-Years

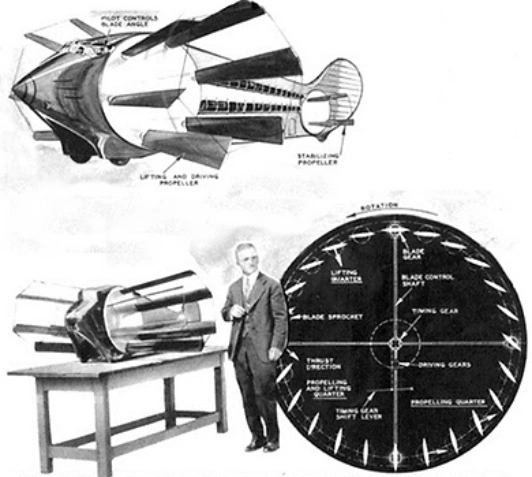

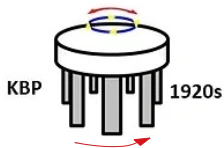

Kirsten Boeing Propeller

SunPlower Propeller technology is similar to the 100-year-old forgotten propeller concept: Kirsten Boeing Propeller (KBP) by German Professor: Frederick Kurt Kirsten.

Even though it was the most efficient propulsion technology, it was not adopted due to the huge hub size (non-scalable), and also it is not optimal for a small RPM range of ICE engines.

These are the 2 main reasons (huge hub & need for wide RPM engine) why this efficient propulsion was forgotten and ignored for 100 years.

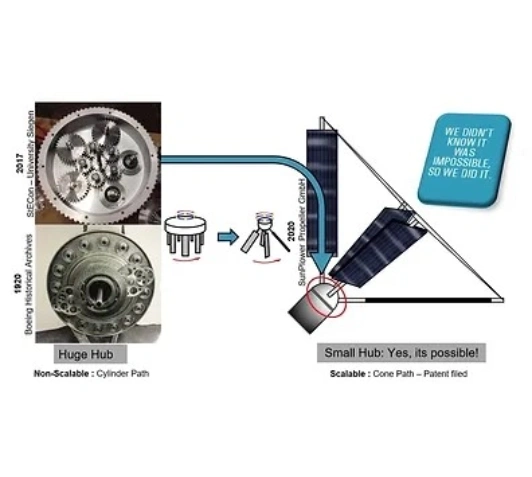

Recently the University of Siegen in NRW Germany has developed the same old large hub non-scalable KBP for hydropower generation, it's a 4 years govt and EU-funded R&D project StECon!!

Uni-Siegen tried very hard to reduce the large hub size (see the image) to a certain extent, however, it was challenging to place all those mechanisms at the zero radius point of a cone to make it ultra-compact and scalable!

SunPlower Propeller Technology

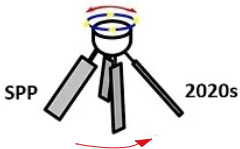

SunPlower Propeller Technology is the world's first compact scalable 2-D directional thrust propeller.

SunPlower Propeller

Blades

SunPlower Propeller blades push the fluid (air/water) similar to birds & fishes. This creates less turbulence, which makes this low noise technology optimal for UAM.

Sunplower Propeller

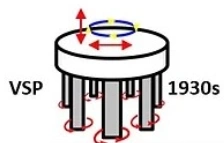

KBP -The Grandfather of Helicopter & Thrust Vectoring Technology: While VSP is known as the father of helicopter technology, KBP's design, developed in the 1920s, laid the foundation for thrust vectoring technology.

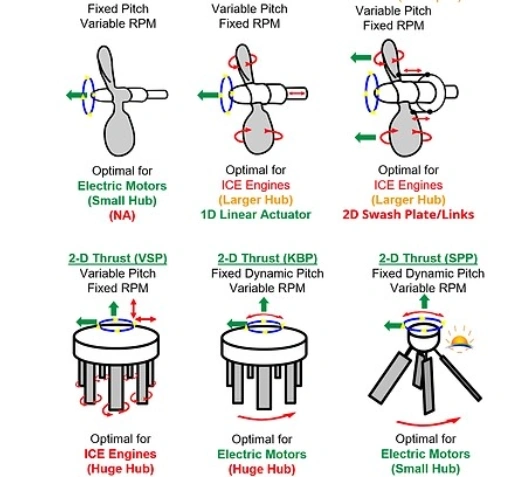

Eliminating Traditional Mechanisms: With modern electric motors offering a wide RPM range, SunPlower eliminates the need for complex variable pitch propellers, swashplates, and thrust vectoring mechanisms in helicopters and VSP systems.

Simplified, Efficient Design: SunPlower's design streamlines thrust generation without the need for traditional, complex components, offering a more efficient and reliable solution for modern propulsion systems.

Lower RPM, Less Noise: SunPlower operates at much lower RPMs than traditional screw propellers, reducing noise and vibration, making it optimal for quieter operations in urban air mobility (UAM), military stealth planes, and submarines.

Nature-Inspired Efficiency: The SunPlower mimics the motion of bird wings and fish fins, creating less turbulence and pushing air or water more efficiently, resulting in greater performance with lower energy consumption.

SunPlower is transforming how we think about aircraft and marine propulsion, making technology simpler, quieter, and more efficient, while pushing the boundaries of what’s possible in the propulsion industry.

Technology Comparison

VSP

(Voith Schneider Propeller)

KBP

(Kirsten Boeing Propeller)

SPP

(SunPlower Propeller)

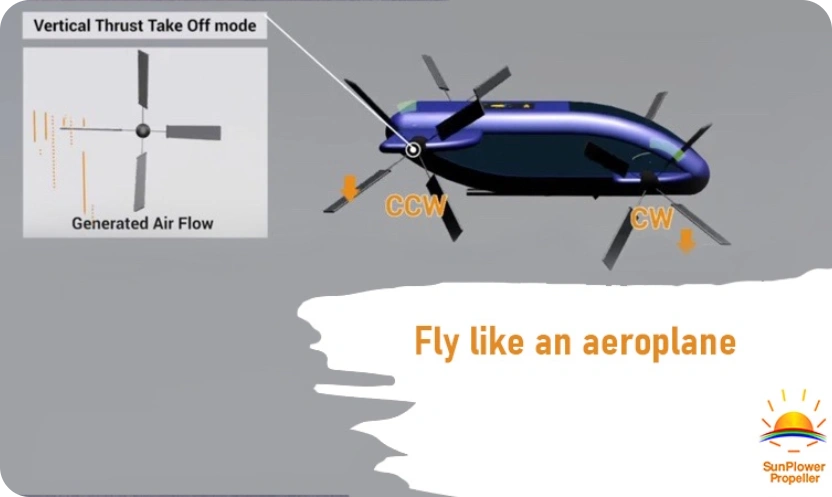

Drones / Air Taxis

SunPlower: Drone Propellers

World's First Compact Directional Thrust propeller:

During Vertical take-off/landing air is pushed down, providing vertical thrust.

Blade's pitch direction is changed to change the direction of thrust, Allowing quick switch to horizontal thrust mode for fast flight.

Thrust vectoring with no hinges & swash plates! It's a very simple 1D control, with no thrust load on the directional thrust control mechanism to rotate the blades.

Enclosed in the hub - eliminating any failures related to environmental contamination for mission-critical applications.

The Benefits of SunPlower for

Communication Towers:

Connectivity Gap:

Half of the world still lacks reliable internet due to poor or no power grids. Operators rely on diesel generators, which are both expensive (50-70 ct/hr) and polluting.

High Maintenance Costs of Solar:

While solar energy is affordable, keeping solar panels clean and maintained is costly. SunPlower’s self-cleaning and self-cooling blades solve this problem, reducing maintenance needs.

Efficient Energy Integration:

SunPlower combines wind and solar energy on the same blades, cutting down on maintenance and eliminating the need for solar trackers, which can be costly and space-consuming.

Reduced Load on Masts:

Unlike traditional wind turbines that waste energy through drag & thrust on the mast, SunPlower uses both lift and drag to put less strain on the mast, improving efficiency and reducing installation challenges.

Compact & Flexible Design:

SunPlower has a small footprint and minimal clearance, making it easy to integrate into existing communication towers or install on independent masts, providing flexibility for operators.

Cost Savings on Installation:

By reducing the need for expensive masts and structural reinforcements, SunPlower can lower installation costs by over 50%, offering a more affordable solution.

Value Over Efficiency:

Operators are more focused on real-world value — practical benefits like cost savings and easy integration — than just theoretical efficiency improvements (+/- 5%).

SunPlower Propeller:

Innovation

for High-Efficiency Aviation

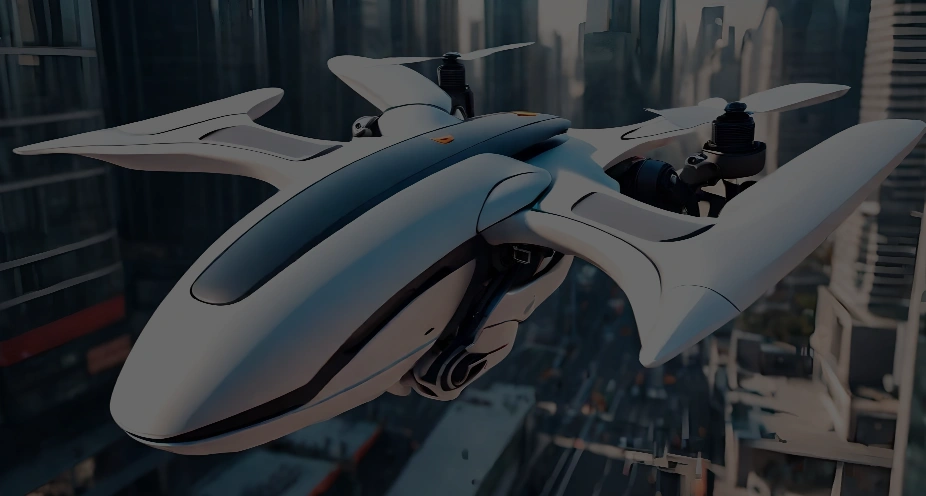

1) Affordable, Reliable, Efficient & Low Noise VTOL

2) Faster & Efficient in thin Air

Elon Musk is right: Electric planes become more efficient as we go higher in altitude (no need for oxygen for the electric engines) which allows more economical and faster flights.

Based on our recent measurements and in-depth analysis of propulsion on Mars conditions (just 1% atmosphere), it's evident that SunPlower Propeller is also optimal and superior for thin air environments.

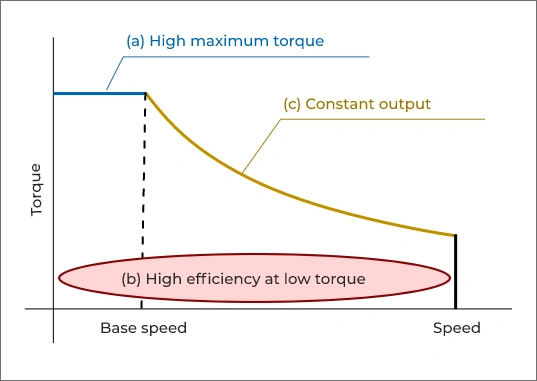

In order to operate both on ground level for eVTOL (low RPM, High torque) and also at high cursing altitudes (high RPM, low torque), there is a need for a large operating range engine without a gearbox or multiple motors. This multiple orders of magnitude range of RPM is possible with a very simple trick. Variable Field Magnetic Motors (Increase motor Kv simply by offsetting the stator) allows higher RPM’s required for higher altitudes with less torque (sufficient in thin air). This not only increases the speed of the motor but also improves the efficiency of the motor by reducing the losses.

Variable field magnet motor

Solar Car

There is also another simple method to increase the Kv rating dynamically (increase RPM) of the electric motor by simply switching motor configuration from Y to ∆ for even higher RPM at higher altitudes (Y configuration is optimal for re-gen during descend). This technology of switching in between Y-∆ configuration is proven & widely used in induction motor starters.

Climbing altitudes is power demanding and if this potential energy is wasted, then it’s not economical at all (reason why the aviation industry is making losses). Next is the solution to this problem.

3) Re-Gen during Descend

We are also exploring possibilities of using Jet streams at higher altitudes for re-charging the batteries in the air. This is only made possible with SPP. The secret lies in eagles flying at high altitudes without flapping wings.

Regenerative braking allows the range of the EV (on the road) to be extended; the efficiency of capturing this energy is reported up to 70%. Regeneration on the ground for EV’s makes sense as the wheel rotates directly proportional to the vehicle's speed for both acceleration (discharge) and deceleration (charge). However, for air vehicles, this does not result in the regeneration of any useful power (proven already) using screw propellers.

Based on our analysis it’s possible to re- generate 15% to 45% of energy with SunPlower Propeller technology during descend. SPP acts as an Air Wheel (actually Air Cone) in the air which can rotate easily during descend at higher RPM – significantly more efficient than screw propellers (high Kv motors used for screw propellers are use-less generators). As SPP needs very low RPM high torque motors (very low Kv); which act naturally like an efficient generator as well when reversed. This enables efficient re-gen with very low configuration change (Y configuration is optimal for re-gen during descend, which generates higher voltages) and also eliminates the need for a separate generator/gearbox.

Today only a few high-end combat military air vehicles have fast decelerating braking capability in the air. As of today UAM vehicles cannot and don’t need this safety feature as there is not much traffic in the air. After a few years’ air traffic is going to increase significantly, imagine driving a car without brakes in busy traffic! Safety is first priority!

SunPlower Propeller allows fast decelerating braking capability in the air. This is not an extra feature that needs to be added – this comes for free from the architecture of the SunPlower Propeller’s 360⁰ directional thrust vectoring capabilities. SPP can also thrust backward at full speed!.

4) Brake in the Air